Fracturing Flowback Fluid Recycling Treatment Agent

Product overview

This treatment agent includes three types of chemicals: FR-T1, FR-T2, and FR-T3. It is primarily used to treat the chemical components in fracturing flowback fluid that affect secondary fluid mixing, enabling the flowback fluid to meet the water quality conditions for re-preparing guar gum. The guar gum solution can be crosslinked normally, allowing for repeated fracturing operations. The recycling rate of fracturing flowback fluid can reach 100%. This product helps reduce environmental pollution caused by oilfield operations to some extent, alleviates the difficulty of water preparation in some oilfields, while it also shortens the water preparation time and reducing economic costs.

Technical indicators

|

Item |

Specification |

||

|

Treatment Agents |

FR-T1 |

FR-T2 |

FR-T3 |

|

Appearance |

Colorless liquid |

Colorless liquid |

Colorless liquid |

|

pH |

pH≈8.5 |

pH≈2 |

微酸性 |

|

Active Ingredient Content |

40.00% |

30.00% |

\ |

Recommended Dosage

|

Treatment Agents |

FR-T1 |

FR-T2 |

FR-T3 |

|

Dosage |

0.25%~0.4% |

0.06%~0.1% |

0.05%~0.15% |

|

Note: The actual dosage of the three agents should be determined by on-site pilot tests to ensure that the pH of the treated return fluid is approximately 6, and the pH of the prepared guar gum fracturing fluid is approximately 7.5. |

|||

Method of Use

The backflow liquid after sedimentation filtration is pumped into the guar gum tank. According to the results of the on-site small-scale test, three treatment agents are added and then pumped evenly.

Packaging and Transportation

1.Packaging: FR-T1 and FR-T2 are packaged in plastic drums, with a net weight of 200Kg per drum; FR-T3 is packaged in plastic bags, with a net weight of 25Kg per bag.

2.Transportation: This product is transported as a standard chemical product.

3.Storage: This product should be stored in a cool, dry place. From the date of production, the shelf life is one year.

Environmental Protection and Safety

1.Skin and Eye Contact: Immediately rinse with plenty of clean water.

2.Ingestion: Drink plenty of warm water, induce vomiting, and seek medical attention.

3.Operational Protection: Wear PVC, PE, or rubber gloves.

Field Application Cases

This product has been successfully applied in certain blocks of the Changqing Oilfield.

Dingbian Well:

Operation Conditions: The oilfield environment temperature was around 30 degrees Celsius. Both the treatment of returned fracturing fluid and the preparation of guar gum were carried out using a Model 700 mixing truck, with each section recovering 120 cubic meters of return fluid, totaling 600 cubic meters of recovered fracturing fluid across five sections.

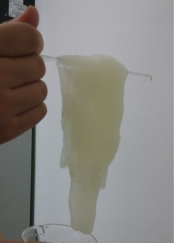

Treatment Results: The recycled fluid was used to prepare 0.3% guar gum with a viscosity reaching 40 mPa·s, and a pH of 7.5~8.0. When the gelation ratio was set at 100:0.3, the viscosity rise time was maintained within 30 seconds, and the pick-up time was 80 seconds. The fracturing operation was completed successfully.

Qingyang Well:

Operation Conditions: The oilfield environment temperature was below 10 degrees Celsius. Both the treatment of returned fracturing fluid and the preparation of guar gum were carried out using a Model 700 mixing truck, with eight horizontal fracturing sections, and a total of 1300 cubic meters of fracturing fluid were recovered from seven sections.

Treatment Results: The recycled fluid was used to prepare 0.3% guar gum with a viscosity reaching 40 mPa·s, and a pH of 7.5~8.0. When the gelation ratio was set at 100:0.3, the viscosity rise time was maintained within 20 seconds, and the pick-up time was 50 seconds. The fracturing operation was completed successfully, and the recycling rate of the returned fracturing fluid reached 100%. Due to local water scarcity, the fracturing operation progress was delayed by about one day per section on average. However, after utilizing the returned fracturing fluid, nearly 200 cubic meters of freshwater preparation could be reduced for each section, allowing the construction progress to return to normal.

Address of the unit: Building 12, No. 8, Heying Road, Nanshao Town, Changping District, Beijing

Tel: 010-64856065

Unit address: 18th Floor, Tianxin Building, No. 27, Fengcheng 2nd Road, Weiyang District, Xi'an

Tel: 029-86101780

©2025 Polydoctor Petroleum Technology Co., Ltd.,Beijing Ministry of Public Security Registration Number:11011402012372 Ministry of Industry and Information Technology Registration Number:Beijing ICP No. 05044633-1