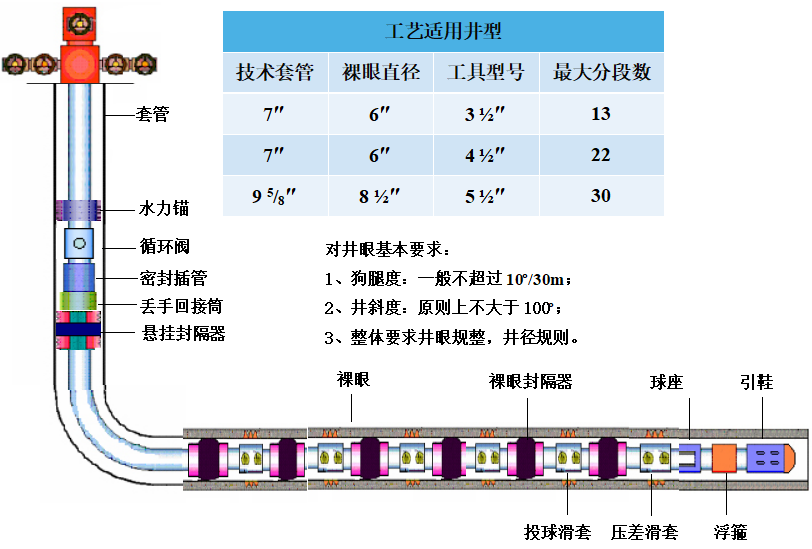

Open-Hole Packer + Ball-Drop Sleeve Staged Fracturing Technology

Technical features

- The time of conventional multi-layer acid fracturing is shortened;

- Horizontal well staged fracturing process is realized by once entry of tools;

- The number of stages is large, which can meet the needs of staged fracturing of ultra-long horizontal wells;

- It realise the integration of completion and modification;

- The ball seat in the sliding sleeve can be drilled and ground to achieve full drift diameter in the wellbore, providing good wellbore conditions for later re-intervention;

- Enhance return on investment.

Technical principles

According to the needs of reservoir development, this technology can use open hole packer and sliding sleeve to pack the horizontal well section into several sections, and open the sliding sleeve by ball throwing during fracturing to carry out targeted construction; it can also be used for zonal oil production and zonal water injection. The open hole packer separates each layer, and each sliding sleeve is equipped with a ball seat, which increases upward in turn, with a stage difference of1/8 or 3/16. it can send the low density ball into the oil pipe in turn, and pump it to the corresponding target layer in the ball seat, the sliding sleeve is opened to treat the production layer, and the sliding sleeve at the toe end is opened according to the principle of pressure difference.

Naked-eye Packer + ball dropping sliding sleeve staged fracturing technology Tubular string

The core components of this pipe string assembly are: the dropping and reinsertion system, the tail pipe suspension packer, the open-hole packer, the ball dropping sleeve, the pressure differential sleeve, the circulation sleeve, etc. The supporting tools have stable performance, simple operation and high construction success rate. Their performance indicators exceed those of similar products at home and abroad.

Open-hole packer

Product features

- It is with expandable rubber support ring, which expands with the expansion of the rubber to protect the rubber cylinder effectively;

- Double piston design reduces the setting pressure;

- Ratchet lock ring mechanism maintains setting force;

- It is with pecial anti-midway setting mechanism;

- It is with the large sealing hole diameter, which sealable drilling can expand 15% of the wellbore.

Technical parameters

|

Model |

Total length/mm |

* Large outside diameter/mm |

* Small diameter/mm |

Outer diameter of rubber cylinder/mm |

Starting pressure/MPa |

Setting pressure/MPa |

Operating differential pressure/MPa |

Operating temperature/℃ |

Seal * Large Bore/mm |

Suitable for naked eyes/in |

Both ends are connected Thread/in

|

|

3 ½″ |

1206 |

φ146 |

φ76 |

φ144.6 |

10~15 |

30 |

80 |

150 |

175 |

6″ |

3 ½″ UP TBG |

|

4 ½″ |

1225 |

φ146 |

φ97.5 |

φ144.6 |

10~15 |

30 |

80 |

150 |

170 |

6″ |

4 ½″ LTC |

|

5 ½″ |

1380 |

φ210 |

φ121.4 |

φ208 |

10~15 |

30 |

80 |

150 |

240 |

8 ½″ |

5 ½″ LTC |

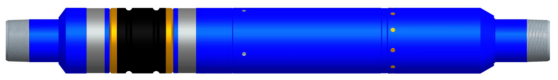

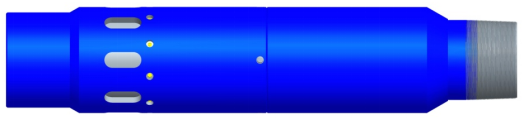

Outline structure drawing

Liner suspension packer

Product features

It is with expandable rubber support ring, which expands with the expansion of the rubber to protect the rubber cylinder effectively;

It has two-way integral slip to ensure no displacement after packer setting;

Ratchet lock ring mechanism maintains setting force;

It is with special anti-midway setting mechanism.

Technical parameters

|

Model |

Total length/mm |

* Large outside diameter/mm |

* Small diameter/mm |

Operating temperature/℃ |

Job Differential pressure/MPa |

Start up Pressure/MPa |

Set seal Pressure/MPa |

Anchoring force/ kN |

Applicable casing/in |

Both ends are connected Thread/in |

|

3 ½″ |

1016 |

φ150 |

φ76.2 |

150 |

80 |

12~15 |

27 |

>800 |

7″ |

上端 4 ½″LTC 下端 3 ½″UP TBG |

|

4 ½″ |

1490 |

φ150 |

φ97.5 |

150 |

80 |

12~15 |

27 |

>800 |

7″ |

4 ½″LTC |

|

5 ½″ |

1275 |

φ210 |

φ121.4 |

150 |

80 |

12~15 |

27 |

>800 |

9 5/8″ |

上端7″LTC 下端5 ½″LTC |

Outline structure drawing

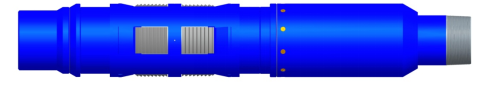

AnchoringPacker

Product features

■ It has two-way integral slip to ensure no displacement after packer setting;

■ Ratchet lock ring mechanism maintains setting force;

■ It is with special anti-midway setting mechanism.

Technical parameters

|

Model |

Total length/mm |

* Large outside diameter/mm |

* Small diameter/mm |

Operating temperature/℃ |

Job Differential pressure/MPa |

Start up Pressure/MPa |

Anchoring Pressure/MPa |

AnchoringForce / kN |

Anchoring * large diameter/mm |

The two ends are connected with threads/in |

|

3 ½″ |

883 |

φ144 |

φ76.2 |

150 |

80 |

12~15 |

27 |

>800 |

φ175 |

3 ½″UP TBG |

|

4 ½″ |

965 |

φ144 |

φ97.5 |

150 |

80 |

12~15 |

27 |

>800 |

φ175 |

4 ½″LTC |

|

5 ½″ |

1150 |

φ210 |

φ121.4 |

150 |

80 |

12~15 |

27 |

>800 |

φ240 |

5 ½″LTC |

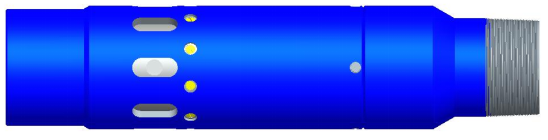

Outline structure drawing

Circulating sliding sleeve

Product features

■ It is with reliable tools, simple structure and quick operation;

■ After the circulation hole is closed, no foreign matter will be left in the pipe;

■ After the ratchet-lock ring mechanism keeps the circulation channel closed, it will not be opened;

■ Opening pressure is adjustable.

Technical parameters

|

Model |

Length/mm |

* Large outside diameter/mm |

Sealing ball/in |

Operating temperature/℃ |

Operating differential pressure/MPa |

Opening pressure/MPa |

Suitable for naked eyes/in |

The two ends are connected with threads/in |

|

3 ½″ |

546 |

φ96 |

1″ |

150 |

70 |

3.3~13 |

6″ |

3 ½″ UP TBG |

|

4 ½″ |

586 |

φ132 |

1″ |

150 |

70 |

3.3~13 |

6″ |

4 ½″ LTC |

|

5 ½″ |

633 |

φ154 |

1″ |

150 |

70 |

3.3~13 |

8 ½″ |

5 ½″ LTC |

Outline structure drawing

Circulating sliding sleeve

Product features

■ It is with reliable tools, simple structure and quick operation;

■ After the circulation hole is closed, no foreign matter will be left in the pipe;

■ Opening pressure is adjustable.

Technical parameters

|

Model |

Length/mm |

* Large outside diameter/mm |

Sealing ball/in |

Operating temperature/℃ |

Operating differential pressure/MPa |

Opening pressure/MPa |

Suitable for naked eyes/in |

The two ends are connected with threads/in |

|

3 ½″ |

610 |

φ127 |

φ76.2 |

150 |

70 |

37±1 |

6″ |

3 ½″ UP TBG |

|

4 ½″ |

662 |

φ146 |

φ97.5 |

150 |

70 |

37±1 |

6″ |

4 ½″ LTC |

|

5 ½″ |

820 |

φ185 |

φ121.4 |

150 |

70 |

37±1 |

8 ½″ |

5 ½″ LTC |

Outline structure drawing

Pitching slip-on

Product features

■ Low density ball has high flowback rate and low flowback pressure;

■ There is a self-locking mechanism in the sliding sleeve to ensure that the sliding sleeve is normally open after opening;

■ The ball seat is made of drillable and grindable materials. After the fracturing operation, it can be reamed and ground to achieve full bore diameter.

■ Opening pressure is adjustable.

Technical parameters

|

Model |

Length/mm |

* Large outside diameter/mm |

Operating temperature/℃ |

Operating differential pressure/MPa |

Opening pressure/MPa |

Flowback pressure/MPa |

Suitable for naked eyes/in |

The two ends are connected with threads/in |

|

3 ½″ |

521 |

φ121 |

150 |

70 |

2.3~22 |

0.9~9.8 |

6″ |

3 ½″ UP TBG |

|

4 ½″ |

584 |

φ146 |

150 |

70 |

2.3~22 |

0.9~9.8 |

6″ |

4 ½″LTC |

|

5 ½″ |

682 |

φ185 |

150 |

70 |

2.3~22 |

0.9~9.8 |

8 ½″ |

5 ½″LTC |

3 ½″ Series tee12 Class Specification: 2″ The following is 1/8 Grade difference; 2″The above is 3/16 Step difference

|

Specification |

1.125″ |

1.250″ |

1.375″ |

1.500″ |

1.625″ |

1.750″ |

|

Specification |

1.875″ |

2.000″ |

2.188″ |

2.375″ |

2.562″ |

2.750″ |

4 ½″ Series tee21 Class Specification: All are 1/8 Step difference

|

Specification |

1.125″ |

1.250″ |

1.375″ |

1.500″ |

1.625″ |

1.750″ |

|

Specification |

1.875″ |

2.000″ |

2.125″ |

2.250″ |

2.375″ |

2.500″ |

|

Specification |

2.625″ |

2.750″ |

2.875″ |

3.000″ |

3.125″ |

3.250″ |

|

Specification |

3.375″ |

3.500″ |

3.625″ |

|

|

|

5 ½″Series tee29 Class Specification: All are 1/8 Step difference

|

Specification |

1.125″ |

1.250″ |

1.375″ |

1.500″ |

1.625″ |

1.750″ |

|

Specification |

1.875″ |

2.000″ |

2.125″ |

2.250″ |

2.375″ |

2.500″ |

|

Specification |

2.625″ |

2.750″ |

2.875″ |

3.000″ |

3.125″ |

3.250″ |

|

Specification |

3.375″ |

3.500″ |

3.625″ |

3.750″ |

3.875″ |

4.000″ |

|

Specification |

4.125″ |

4.250″ |

4.375″ |

4.500″ |

4.625″ |

|

Outline structure drawing

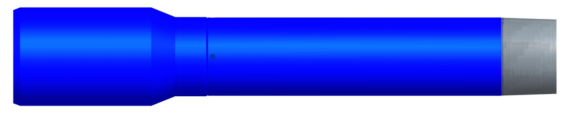

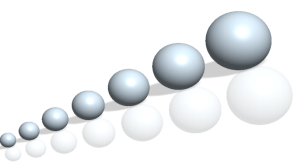

Low-density alloy fracturing balls

Product features

■ This ball is made of special materials and processed by special techniques, featuring high wear-resistance, high hardness and resistance to erosion.

■ It is with the high compressive strength, high temperature resistance;

■ It is resistant to chemical substances such as acid, alkali and salt;

■ It is with low density, and easy flowback。

Technical parameters

|

Densityg/cm3 |

Operating temperature/℃ |

Take the strain/MPa |

|

1.55~1.90 |

150 |

80 |

Outline structure drawing

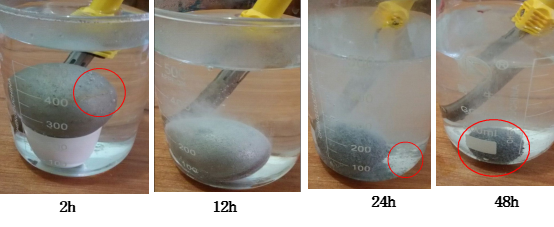

Soluble fracturing balls

Product features

■ The ball uses a specialThe material and the process have the characteristics of high wear resistance, high hardness and erosion resistance;

■ It is with high compressive strength, and high temperature resistance;

■ It is resistant to chemical substances such as acid, alkali and salt;

■ After a certain period of time, it can dissolve quickly.

Technical parameters

|

Densityg/cm3 |

Operating temperature/℃ |

Take the strain/MPa |

Complete dissolution time/h |

|

2.6~2.8 |

150 |

80 |

<72 |

Experimental test: The solubility of soluble spheres in aqueous solution increases with the passage of time and the rise of temperature. The dissolution rate intensifies.

Release and reinsertion system

Product features

■ It utilizes a hydraulic and mechanical composite release for safety and reliability.

■ The back-plug connector features a self-locking mechanism, ensuring reliable sealing performance upon reinsertion.

Technical parameters

|

Model |

Length/mm |

* Large outside diameter/mm |

* Small inside diameter/mm |

Operating temperature/℃ |

Operating differential pressure/MPa |

Drop itDifferential pressure/MPa |

Suspended load/kN |

Applicable casing/in |

Both ends are connected Thread/in |

|

3 ½″ |

1160 |

φ148 |

φ76.2 |

150 |

70 |

22~25 |

>800 |

7″ |

3 ½″ UP TBG |

|

4 ½″ |

1190 |

φ150 |

φ97.5 |

150 |

70 |

22~25 |

>800 |

7″ |

4 ½″ LTC |

|

5 ½″ |

1215 |

φ190 |

φ121.4 |

150 |

70 |

22~25 |

>900 |

9 5/8″ |

5 ½″ LTC |

Outline structure drawing

Address of the unit: Building 12, No. 8, Heying Road, Nanshao Town, Changping District, Beijing

Tel: 010-64856065

Unit address: 18th Floor, Tianxin Building, No. 27, Fengcheng 2nd Road, Weiyang District, Xi'an

Tel: 029-86101780

©2025 Polydoctor Petroleum Technology Co., Ltd.,Beijing Ministry of Public Security Registration Number:11011402012372 Ministry of Industry and Information Technology Registration Number:Beijing ICP No. 05044633-1