Continuous Dragging Jet Perforation and Annulus Fracturing Technology

Technical features

- The number of fracturing sections is not limited;

- One trip of string can realize multi-section transformation and shorten the operation time;

- The collar positioning device enables precise positioning of perforation and fracturing locations. For thin layers, and it can achieve targeted fracturing.

- Each perforated horizon can be selectively fractured without separate perforation;

- No other tools are needed for auxiliary packing, and full drift diameter is realized after fracturing;

- The tool can be set and unset for many times;

- The operation is simple and fast, and the construction cost is reduced.

Technical principles

The continuous drag sand-jetting perforating and annular fracturing technology integrates two techniques: hydraulic sand-jetting perforating and multi-stage fracturing with added sand in annulus. It enables one trip of pipe string and one set of tools to complete multiple stages of perforating and fracturing operations. Perforating is accomplished by the hydraulic jetting of sand-jetters in the tool string. Inter-layer isolation is achieved by the repeated setting and unsetting of drag-type bottom-sealing packers. After fracturing, all the pipe strings are pulled out to achieve full borehole diameter.

Continuous drag sand blasting perforation and annular fracturing Process column string

The string is consists of:Multipurpose back-off, sand blaster, drag bottom packer, collar locator, storage pressure gauge (optional). It is composed of tools, and the supporting tools have stable performance, simple operation and high success rate of construction.

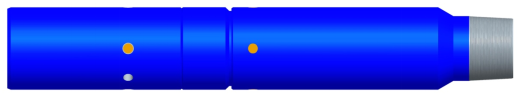

Drag bottom seal packer

Product features

- The special rubber cylinder structure ensures reliable sealing performance. The alloy swivel teeth provide firm anchoring. It is suitable for various steel grades of casing.

- It is with multi-function combination of circulation, sealing, anchoring and transposition, and it is also with compact structure;

- Setting and unsetting can be easily realized by lifting and lowering the string, and the operation is convenient and simple;

- It has a special sand prevention function to prevent the possible sand jamming problem that may occur during operation.

Technical parameters

|

Content |

Parameter |

||

|

Model |

TDF-95 |

TDF-116 |

TDF-120 |

|

* Large outside diameter/mm |

φ95 |

φ116 |

φ120 |

|

Track travel/mm |

161 |

235 |

|

|

Total length/mm |

1460 |

1415 |

|

|

Operating differential pressure/MPa |

60 |

60 |

|

|

Setting thrust/kN |

>10 |

>10 |

|

|

Setting times/Set |

>30 |

>25 |

|

|

Operating temperature/℃ |

120 |

120 |

|

|

Applicable casing/in |

4 1/2″ |

5 1/2″ |

|

|

Both ends are connected with buckle type/in |

2 3/8″UP TBG |

2 3/8″UP TBGOr2 7/8″UP TBG |

|

Outline structure drawing

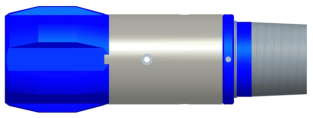

Multifunctional release

Multifunctional release

■ It employs hydraulic and mechanical compound release;

■ It is with simple operation and reliable performance.

Technical parameters

|

Content |

Parameter |

||

|

Model |

DDS-90 |

DDS-100 |

|

|

* Large outside diameter/mm |

φ90 |

φ100 |

|

|

* Small diameter/mm |

φ32 |

φ46 |

|

|

Total length/mm |

612 |

620 |

|

|

Pressure bearing/MPa |

70 |

||

|

Operating temperature/℃ |

150 |

||

|

Drop handball diameter/mm |

φ35 |

φ50 |

|

|

Release pressure/ MPa |

22~25 |

||

|

Mechanical release torque/kN∙m |

2~4 |

||

|

Number of laps reversed |

15 |

||

|

Applicable casing/in |

4 1/2″ /5 1/2″ |

5 1/2″ |

|

|

The two ends are connected with threads/in |

2 3/8″UP TBG |

2 7/8″UP TBG |

|

Outline structure drawing

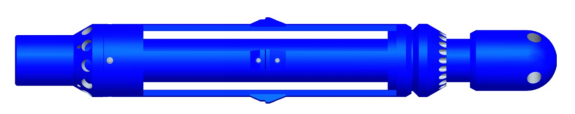

Sand blaster

ProductsCharacteristic

■ The nozzle is made of special alloy material with hardness HRA greater than 95 and excellent wear resistance;

■ With sand blaster at 1.2m3 under the displacement of/min, it can operate for more than 20 floors;

■ The outer surface of the sand blaster is equipped with a hard alloy protective sleeve to prevent the back splash of sand blasting from eroding the body.

Technical parameters

|

Content |

Parameter |

|

|

Model |

PSQ-90 |

PSQ-95 |

|

* Large outside diameter/mm |

The righting partφ95mm Body outer diameterφ90mm |

The righting partφ116mm Body outer diameterφ95mm |

|

* Small diameter/mm |

φ38 |

φ44 |

|

Total length/mm |

330 |

330 |

|

Nozzle diameter/mm |

φ4.5/φ4.7/φ5.5 |

φ4.5/φ4.7/φ5.5/φ6.35 |

|

Number of nozzles/Only |

4 |

4 |

|

Pressure bearing/MPa |

70 |

70 |

|

Operating temperature/℃ |

150 |

150 |

|

Tensile strength/kN |

>800 |

>800 |

|

Applicable casing/in |

4 1/2″ |

5 1/2″ |

|

The two ends are connected with threads/in |

2 3/8″UP TBG |

2 3/8″UP TBGOr2 7/8″UP TBG |

Outline structure drawing

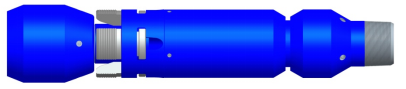

Anti-sand type mechanical couple positioner

ProductsCharacteristic

■ It has a special sand prevention function to prevent the possible sand jamming problem that may occur during operation.

■ The body adopts a special structure. By taking advantage of the elasticity of the body, it is able to generate an induced signal when the over-tightened area is expanded or contracted at the joint.

Technical parameters

|

Content |

Parameter |

|

|

Model |

CCL-90 |

CCL-114 |

|

* Outer diameter of large steel body/mm |

Body outer diameterφ90 Position the outside diameter of the fixture blockφ108 |

Body outer diameterφ114 Position the outside diameter of the fixture blockφ130 |

|

* Small diameter/mm |

φ31 |

φ50.8 |

|

Total length/mm |

710 |

750 |

|

Operating differential pressure/MPa |

70 |

70 |

|

Operating temperature/℃ |

150 |

150 |

|

Applicable casing/in |

4 1/2″ |

5 1/2″ |

|

Both ends are connected with buckle type/in |

2 3/8″UP TBG |

2 3/8″UP TBGOr2 7/8″UP TBG |

|

Coupling passing induction signal |

Hanging weight is available10~20kNFluctuation of |

|

Outline structure drawing

Sand control type hydraulic anchor

Product features

■ It is with alloy slip teeth, firmly anchored, suitable for all kinds of steel casing;

■ The anchor can be released by releasing the pressure and lifting the string;

■ It is equipped with a special sand control function to prevent potential sand jamming issues during operations.;

■ It is with the simple structure, convenient operation, safety and reliability.

Technical parameters

|

Content |

Parameter |

|

Model |

FSYM-114 |

|

* Large outside diameter/mm |

φ114 |

|

* Small diameter/mm |

φ34 |

|

Total length/mm |

642 |

|

Starting pressure/MPa |

>5 |

|

Anchor pressure/MPa |

>8 |

|

Anchoring force/kN |

>800 |

|

Pressure bearing/MPa |

70 |

|

Operating temperature/℃ |

150 |

|

Applicable casing/in |

5 1/2″ |

|

The two ends are connected with threads/in |

2 3/8″ UP TBGOr2 7/8″ UP TBG |

Outline structure drawing

Address of the unit: Building 12, No. 8, Heying Road, Nanshao Town, Changping District, Beijing

Tel: 010-64856065

Unit address: 18th Floor, Tianxin Building, No. 27, Fengcheng 2nd Road, Weiyang District, Xi'an

Tel: 029-86101780

©2025 Polydoctor Petroleum Technology Co., Ltd.,Beijing Ministry of Public Security Registration Number:11011402012372 Ministry of Industry and Information Technology Registration Number:Beijing ICP No. 05044633-1