Piston compressor

Product Introduction

The compressor adopts a piston type D-shaped structure, oil-free lubrication and two-stage (three-stage) pressurization. The driving motor is directly connected with the device body. The device adopts a liquid cooling and forced air cooling cooling mode. The device adopts a PLC full-automatic control system with a self-diagnosis monitoring function. The whole unit is arranged on the skid-mounted base. The unit has compact structure, stable operation, convenient maintenance, low noise, small vibration and high degree of automatic control. It can realize unattended operation and meet the digital management of intelligent oilfield construction.

The installation of the compressor device at the wellhead or well group can realize pressurized gas production, reduce the wellhead back pressure,and improve the transmission capacity, reduce the formation abandonment pressure. It can also reduce the fluid resistance in the wellbore, increase the lifting pressure difference, improve the drainage capacity, release the natural gas at the bottom of the well as far as possible, and ensure that the natural gas at the bottom of the well can enter the gas transmission pipeline network, which can effectively prolong the development life of the gas field and increase the gas production and income.

Applicable Range

Function and Features

1)The mainframe employs symmetric balanced multistage compression, with features of low vibration, easy maintenance, and reliable performance.

2)The mainframe adopts a cooling method that combines air cooling and liquid cooling, effectively addressing the common issue of high temperatures during prolonged high-speed operation of compressors. This results in stable exhaust temperatures and high working efficiency.

3)It can handle variable suction and discharge pressures, with a wide intake pressure range as low as 0.2MPa; a high exhaust pressure, up to 6.3MPa; and the exhaust pressure has nothing to do with the intake pressure, and is highly applicable;

4)Capable of handling variable suction and discharge pressures, the system has a wide range of intake pressures, starting as low as 0.2MPa; it can achieve high discharge pressures up to 6.3MPa. Additionally, the discharge pressure is independent of the intake pressure, providing strong adaptability.

5)It features an independent lubrication system; the piston rings and packing use special oil-free lubricating materials, which are wear-resistant with a long service life.

6) The control system of the device adopts PLC for fully automatic control to enable multi-faceted detection and early warning functions for the equipment in the unmanned operation.

7)The control system is of the device features, self-detection and health management functions, automatic fault diagnosis and prompting capabilities. It employs an interlock mechanism to ensure safety and reliability, thereby it can enhance equipment operation efficiency.

Technical Parameters

|

Model |

DW-2.3/5-40 |

DW-4.2/5-40 |

DW-6.5/5-40 |

DW-5/20-63 |

|

Structural type |

Horizontal symmetrical balance piston type, two-row two-stage compression |

Horizontal symmetrical balance piston type, two-row two-stage compression |

Horizontal symmetrical balance piston type, two-row two-stage compression |

Horizontal symmetrical balanced piston type, two-row three-stage compression |

|

Nominal volume flow |

2.3m3/min |

4.2m3/min |

6.5m3/min |

5m3/min |

|

Inlet air pressure |

0.2-0.5MPa |

0.2-0.5MPa |

0.2-0.5MPa |

0.2-2MPa |

|

Discharge pressure |

≤4.0MPa |

≤4.0MPa |

≤4.0MPa |

≤6.3MPa |

|

Air displacement |

≤10000Nm3/d \n |

≤30000Nm3/d \n |

≤50000Nm3/d \n |

≤100000Nm3/d \n |

|

Intake air temperature |

≤40 ℃ |

≤40 ℃ |

≤40 ℃ |

≤40 ℃ |

|

Gas transmission temperature |

≤120℃ |

≤120℃ |

≤120℃ |

≤120℃ |

|

Lubricating oil temperature |

≤80 ℃ |

≤80 ℃ |

≤80 ℃ |

≤80 ℃ |

|

Rotating speed |

740r/min |

740r/min |

740r/min |

740r/min |

|

Shaft Power |

70kW |

110kW |

150kW |

210kW |

|

Cooling method |

Air Cooling+Water cooling |

Air Cooling+Water cooling |

Air Cooling+Water cooling |

Air Cooling+Water cooling |

|

Lubrication mode |

Crankshaft, connecting rod and crosshead are lubricated by oil pump |

Crankshaft, connecting rod and crosshead are lubricated by oil pump |

Crankshaft, connecting rod and crosshead are lubricated by oil pump |

Crankshaft, connecting rod and crosshead are lubricated by oil pump |

|

|

Oil-free lubrication of cylinder and packing |

Oil-free lubrication of cylinder and packing |

Oil-free lubrication of cylinder and packing |

Oil-free lubrication of cylinder and packing |

|

Equipped with power |

Explosion-proof variable frequency motor90kW、740r/min、380V、50Hz |

Explosion-proof variable frequency motor132kW、740r/min、380V、50Hz |

Explosion-proof variable frequency motor185kW、740r/min、380V、50Hz |

Explosion-proof variable frequency motor250kW、740r/min、380V、50Hz |

|

|

Oil pump motor0.75kW、0.5kW |

Oil pump motor1.1kW、0.5kW |

Oil pump motor1.5kW、1.1kW |

Oil pump motor2.2kW、1.1kW |

|

|

Fan motor:Air Path2.2kW. Oil circuit1.1kWWaterway3kW

|

Fan motor, air circuit2.2kW. Oil circuit1.1kWWaterway3kW |

Fan motor:Air Path2.2kW. Oil circuit1.1kWWaterway3kW |

Fan motor:1.5kW×4 |

|

Connection mode |

Direct connection |

Direct connection |

Direct connection |

Direct connection |

|

Noise |

80dB |

80dB |

80dB |

80dB |

|

Startup mode |

Soft start |

Soft start |

Soft start |

Soft start |

|

Overall dimension of the unit |

5900×3200×2350 mm |

6700×3200×2350 mm |

6700×3200×2350 mm |

8500×3200×2350 mm |

|

Unit weight |

~8t |

~12T |

~15t |

~18.5t |

Core technologies and key components

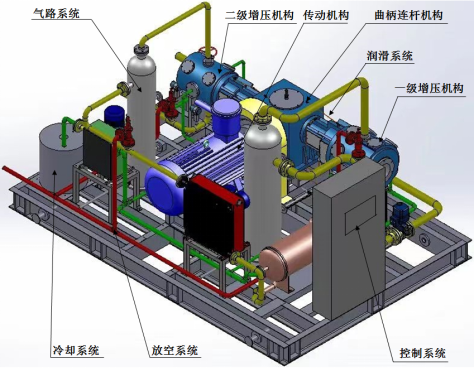

The tightening device consists of a transmission mechanism, a crank connecting rod mechanism, a pressurizing mechanism, a gas path system, a cooling system, an emptying system, a lubricating system and a control system unit.It adopts the full-automatic control system with the function of self-diagnosis and monitoring. The whole unit is arranged on the skid-mounted base. The unit has the advantages of compact structure, stable operation, convenient maintenance, low noise, small vibration, safety and reliability, and high degree of automatic control. It can realize unattended operation and meet the digital management of intelligent oilfield construction.

Execution Standards

1.JB/T 5297-1991 Basic Parameters for Reciprocating Natural Gas Compressors Used in the Petroleum Industry

2.JB/T 8685-1998 Design and Construction Specifications and Data Sheets for Reciprocating Compressors Used in Process Engineering

3.GB/T 20322-2006 Reciprocating Compressors for the Petroleum and Natural Gas Industry

Application Cases

▶ Case 1:

There is a coalbed methane platform in Linxing, ShanxiWells, with a production time from March to April,2003. After 1 years of exploitation, the oil pressure of each well was equal to the transmission pressure, and the well was forced to shut in and re-pressurize, and the gas production and liquid carrying capacity of each well on the platform were greatly limited.The on-site process transformation of the equipment would be completed in May,2024.Through the operation of the compressor to reduce the oil pressure of each wellhead, it can achieve low oil pressure production, enlarge the production pressure difference, improve production, meet the critical liquid carrying flow, meet the requirements of gas well drainage, and improve oil recovery; At the same time, the pressure of the well platform is increased through the pressurization equipment to ensure that the gas enters the pipeline network smoothly, meet the requirements of pipeline transportation, prolong the continuous production cycle of the gas well, and increase the gas production of the platform as a whole.The economic benefits are substantial.

▶ Case 2:

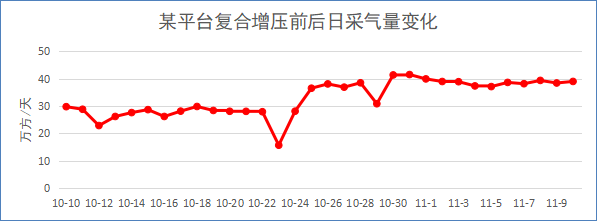

A shale gas well platform in the southwest has a total of 6 wells, which have been in production for nearly one and a half years. On June 15, 2024, intelligent injection and drainage technology measures were implemented on the platform. The booster equipment was put into operation on October 24. Before the composite process was put into production, the average daily gas production over 15 days was 269,600 cubic meters per day. After the booster, the average daily gas production over 15 days reached 381,400 cubic meters per day, an increase of 111,800 cubic meters per day, with a growth rate of approximately 41.5%. The composite process achieved increased production in the initial stage and now it is currently producing steadily.

Address of the unit: Building 12, No. 8, Heying Road, Nanshao Town, Changping District, Beijing

Tel: 010-64856065

Unit address: 18th Floor, Tianxin Building, No. 27, Fengcheng 2nd Road, Weiyang District, Xi'an

Tel: 029-86101780

©2025 Polydoctor Petroleum Technology Co., Ltd.,Beijing Ministry of Public Security Registration Number:11011402012372 Ministry of Industry and Information Technology Registration Number:Beijing ICP No. 05044633-1